The flat part of the curve represents the period of time where the failure rate is constant. Over time and with feedback garnered from burn-in testing, processes and equipment parameters can be improved in key fabrication steps to reduce all areas of the failure rate bathtub curve. Also, extrinsic processes not related to device fabrication itself, such as packaging and connectivity, are also common causes of early-stage failures. As fabrication processes and equipment reach their tolerance limitations, an unavoidable early failure rate increase is observed. These systems require higher frequencies of operation which drive device sizes to decrease geometries and line spacings. A good example comes from the requirements of new communications networks for large bandwidth channels needed for video streaming and ultra-fast data transfer.

As system application requirements become more advanced the requirements for device manufacturing processes are pushed to their resolution and tolerance limits. A high early failure rate results from uncontrollable anomalies that occur during the manufacturing process. The bathtub curve is a result of the limitations of manufacturing processes and equipment capabilities implemented in the fabrication of the device. The resulting curve resembles a cross-section of a bathtub with sharp curves on each end and a flat bottom. The name comes from the shape of the graph obtained when you plot the failure rate of parts against their time in operation. The time-dependent failure rate of electronic components follows a pattern known as the bathtub curve. Further, an ongoing burn-in test plan is essential for statistically-based process control management of the production line.īurn-in results are the sight-glass for detecting and improving the quality and reliability assurance over the production life cycle of the device.

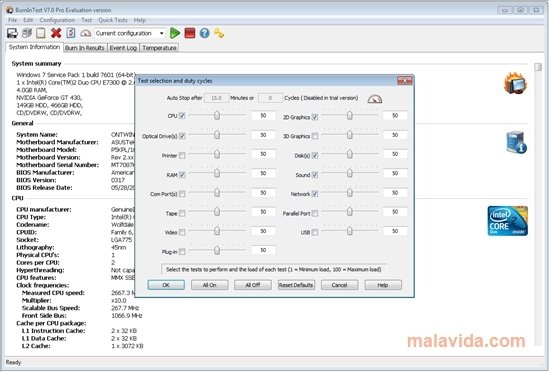

The elimination of suspect devices from the field population significantly increases the probability that devices will operate to customer expected levels of reliability. A burn-in test places devices under typical operating conditions in a controlled environment to cause defective products to fail before they reach the end-user. Any atypical performing device is removed from the lot and not sent out to the customer.

This environmental stress “burn-in” test, when performed over a large sample size of identical device types, allows the manufacturer to capture a statistically based snapshot of the field performance of the device. Perhaps the best approach to achieve this goal would be to perform a short but enhanced test case of the device in the actual field stress environment, essentially validating the performance signature of the field conditions. However, burn-in at this level can show faults that burn-in of components cannot find, such as dry or cold solder joints and contact problems.įor more complex devices, dynamic burn-in is used where thermal stress is combined with dynamic simulation of inputs to provide worst-case operating conditions.In response to this expectation, manufacturers have developed ways to enhance the probability of delivering the highest possible reliability to the end-user. Burn-in of a board or an assembly is difficult because different components have different limits. Click here to see our latest technical engineering podcasts on YouTube.Īs a general rule, it is best to burn-in at the component level when the cost of testing and replacing parts is lowest. Burn-in is applied to products as they are made, to detect early failures caused by faults in manufacturing practice. 20 cycles from -10 to 70☌ ramped at +☌/mm) is used. 125☌ for 168 hours) or environmental stress screening (e.g. It usually requires the electrical testing of a product, using an expected operating electrical cycle (extreme of operating condition), typically over a time period of 48-168 hours.

0 kommentar(er)

0 kommentar(er)